Puffed food has long been popular with many consumers because of its good palatability, unique taste, easy to carry, easy to eat, and long shelf life. As a Double Screw Extruder Factory, let's talk about the development trend of grain puffed food.

1. Nutritional grain puffed food.

Fat, carbohydrates and protein are the main components of traditional puffed foods. From the component structure, it is a food with high fat, high calorie and low crude fiber. In addition, most of the traditional puffed foods contain more monosodium glutamate and salt and food additives. A large amount and long-term consumption will cause high oil and calorie intake, insufficient nutrient intake, and easily lead to obesity. With the gradual improvement of people's consumption awareness, food nutrition has become the main focus of consumer shopping. As a puffed food, the most important problem in the development of the industry at present is to solve the nutrition of products and change people's previous understanding of their “junk food”.

2. Low energy grain puffed food

From the perspective of compositional structure, traditional grain puffed foods are high-fat, high-calorie, low-fiber fiber foods. Long-term consumption can cause high inhalation of oils and fats, insufficient nutrient intake, and easy to lead to fat. Therefore, low energy is also an important development direction of snack foods.

Many grain puffed foods have a frying process in their processing, so their energy control is closely related to their oil content, which in turn depends on the absorption of oil during processing. The selection of a material having a high solid content can shorten the time required for frying, and the raw material can be pre-dried or partially dried before frying to shorten the frying time. To control the oil absorption during the frying process, the frying temperature is also critical. The raw materials should be fried at the highest possible temperature to shorten the frying time and reduce the oil absorption. In addition, the larger the surface area of the raw material, the greater the oil absorption. Therefore, the oil content of the wafer is low.

3. High temperature puffing technology

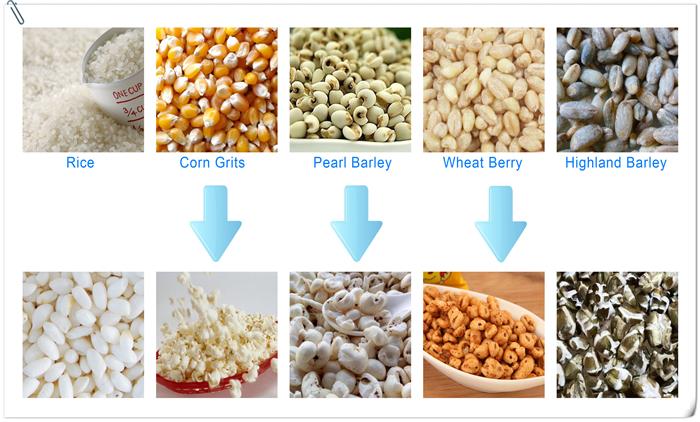

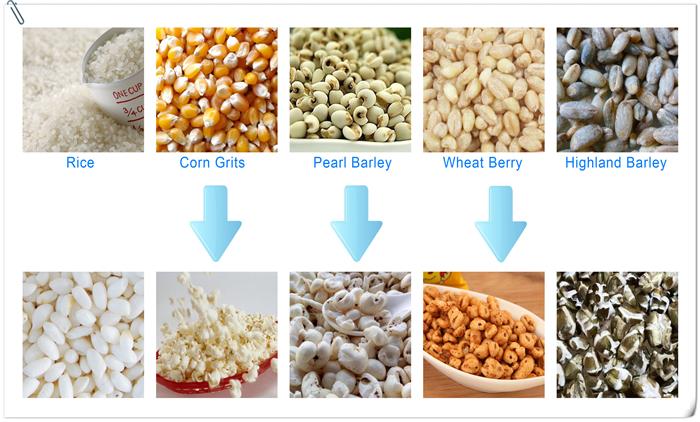

High-temperature puffing is the circulation of hot air to achieve the vaporization of water, and then the overall expansion of the animal material. At present, cereal puffed foods produced by high temperature puffing technology have been produced.

Compared with the snack food made by frying, the high temperature puffing has low oil content, the product contains no oil or less oil, and is crisp and delicious. It has fast heating speed, short time, high product quality, uniform heating and equipment footprint. Less features. It can be foreseen that high temperature puffing technology is a direction for the development of puffed food production technology.

Cereal is the main food resource for human survival. The grain processing industry shoulders the heavy responsibility of providing humans with a basic dietary source and ensuring human health. The world's grain processing industry is moving towards the use of modern high technology, increasing the development of limited grain resources and increasing the added value of cereal products.

Our company offers the Pop-rice Puffing Machine. Welcome to contact us.

English

English  Español

Español  Pусский

Pусский  عربى

عربى  日本語

日本語